I recently received this email:

I found out about you by searching around for information on green powders. I am very confused about the way the powders are made and how to compare them.

This message came on the tail end of a phone conversation I had with another customer who also had questions about how Incredible Greens was made.

In general questions like “where is your product made?” “how do you choose your ingredients?” and “is it safe?” come up pretty frequently, so I’ll use this piece to answer these questions in more detail.

My answer to the latter question will apply to Incredible Greens specifically and likely to most supplement manufacturers in general. The process is fairly standardized.

However, please keep in mind that I only represent Health Kismet. I am not a representative of any other companies. What I’m about to say is my own opinion and may not apply to other cases.

How Greens Powders Are Made

The basic process of making a greens powder is fairly simple. If you wanted you could do it in your home, but it’d be much less economical than buying the same supplement from someone else who does it professionally.

The process can be broken down into three different stages:

1). The ingredients are sourced and delivered

2). The ingredients are condensed into a powder or extract

3). The ingredients are bottled and stored in a facility until they’re ordered.

Let’s talk about this process in more detail.

Sourcing the Ingredients

A supplement company has a few choices when it comes to deciding how ingredients for its product are sourced. Most manufacturers will have agreements with different suppliers for a vast majority of ingredients that can legally be put into a supplement. You can order the ingredients directly through them, or go through independent suppliers directly.

Using ingredients from the manufacturer is the most convenient method and sufficient most of the time. They’re legally required to maintain certain standards of quality and will have better prices than the supplement company. However, some companies will choose to bypass their manufacturer and go directly with a supplier. This could be because the supplier is certified in a particular way (kosher, vegan, non-gmo, organic, etc), has certain ingredients not offered by the manufacturer, or perhaps offers special pricing that the manufacturer doesn’t offer.

The process itself works like a marketplace. The supplement company will approach the manufacturer with the different ingredients it wants to put in its supplement and any additional requirements (vegan, kosher, agency specific certification, etc) and the manufacturer will return with a quote for the amount they need.

If you go through an independent agency they’ll typically offer a variety of ingredients to choose from. Some companies specialize in growing probiotics, others herbs and grasses, some others work through a specific certification agency that you can put on your products.

Turning the Ingredients Into A Powder

So you’ve decided on how these superfoods are going to be put into your mixture. How do they actually get turned into a powder? Do they still qualify as the original foods if they’re in powder form?

When prepping foods for a supplement you have four different options:

- Grind the food into a powder

- Extract the juice from the food

- Extract the juice and turn that into a powder

- Extract an isolate from the food that condenses certain nutrients in greater quantities

Taking a food and turning it into a powder happens in two steps.

- You have to dehydrate the food

- You have to crush it until it turns into a dust

If you wanted to you could do this at home. You can buy a dehydrator and put the dry plant leaves in a vitamix or food processor and turn it into a powder.

At a manufacturing facility the equipment is much more expensive and finely tuned, but the basic process is the same. The biggest difference is that the conditions for evaporation and powderizing are controlled to ensure ingredient purity.

Taking the juice out of something works much like doing it at home, but again at larger scale.

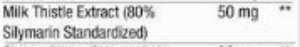

At times you’ll see an ingredient label that looks like this:

In this case the ingredient is a milk thistle extract, which is 80% silymarin by volume. (Silymarin is the biologically active component of milk thistle. More on that here. )

If an ingredient is an extract that means certain parts of the plant were separated and then condensed into a powder or liquid. The separation process typically happens by pulverizing the food and then mixing it with a solvent of some sort to separate the different components of the plant and dry the necessary parts you need for your supplement.

So why would a supplement company choose one form of ingredient over another?

Here are the relevant strengths/weaknesses of each type:

- powders or the whole food (ie, wheatgrass/wheatgrass powder, etc) are the most “pure” form of the ingredient. They’re also the bulkiest, usually the worst tasting, and sometimes not as nutritious as other forms

- the “juice” or “juice powder” of an ingredient is more condensed, often sweeter than the whole root, is absorbed more quickly, and sometimes more nutritious. The relative nutritiousness of the whole root vs. the juice of the root often depends on how much of the plant’s nutrients are stored up in the fibrous part of the plant which can’t be extracted.

- The extracts are often the easiest to manufacture and are particularly beneficial when the nutrients of a particular food are bottled up in a few compounds. This is particularly true when dealing with certain medicinal herbs such as milk thistle or ginkgo biloba. These plants are very bitter tasting, don’t mix well, and their health benefits are concentrated in a handful of unique biological compounds which do wonderful things for the body. Sucking them out of the plant helps preserve some semblance of taste and get the best the plant has to offer. It also frees up more room in the powder for other types of foods which do more good in their bulk form.

Sometimes the process of turning a food into a powder, food juice, food juice powder or food extract is done by the supplier and other times it’s done at the manufacturing plant itself.

Mixing and Bottling the Supplement

Once the ingredients are in their proper form it’s time to mix and bottle them so they can be sold as a supplement. This is almost entirely done by machines.

Instead of explaining it, I’ll leave the description to a video (this is the manufacturing plant where Incredible Greens is made):

Hopefully that helps.

Some Commonly Asked Questions

If you’ve made it this far, you still might have a few questions lingering in the back of your head.

Here are some brief answers to common ones:

How Do I Know The Ingredients Are Pure?

Most suppliers work in accordance with some sort of quality assurance agency such as the national organic standards board or something similar so they can be certified as having a certain level of quality.

The FDA also requires that ingredients are tested for purity and potency before they’re put into a supplement.

Does A Powder Still Qualify As A Food? Is it as nutritious?

Powders will maintain most if not all of the nutritional qualities of the food they’re made from. The powder form itself makes the nutrients more easily absorbable, especially if they’re typically locked up within the cell walls of the food.

Sometimes a food will be turned into a powder with some application of heat which will degrade the nutrients. It’s also possible that the powdering process may involve the use of some chemical applicants which might leave residues on the food or dilute the nutritional value of the ingredient.

The best way to get around this is to buy from a supplement manufacturer that makes their supplement from a manufacturer that’s GMP certified. Those are the guys that require supplement ingredients to be held to a certain standard of purity, as stated on the label. (If you’re curious, here’s the label for the facility that makes Incredible Greens).

Can the Ingredients in Greens Powders Still Be Raw? Are They Still Considered Whole Foods?

You can definitely turn a food into a powder or extract without heat treatment. It’s a stretch in my opinion to consider an extract a whole food, but the powders still come very close, and still have the health benefits I stated above.

How Can I Compare Superfood Powder Products?

Read my superfood powder buying guide.

Please let me know if you guys have any more questions. Thanks!

Hello i need to learn how to take a plant and run it threw a jucer making it liquid then i need to turn it to concrated powder my name is stanley kafara u can e mail me at infinitykafaraiii@yahoo.com id be gratfull if u can help me….

LikeLike

I really apreciate your contribution with this article.

How are powders from juice made?

And what if before dehydrating we juice the ingredient first and only dehydrate the solids?

Those questions are reeally interesting for me.

LikeLike